Personal Account

Personal Account

Plant for induction melting "PPI-0.45"

Plant for induction melting "PPI-0.45"

Description

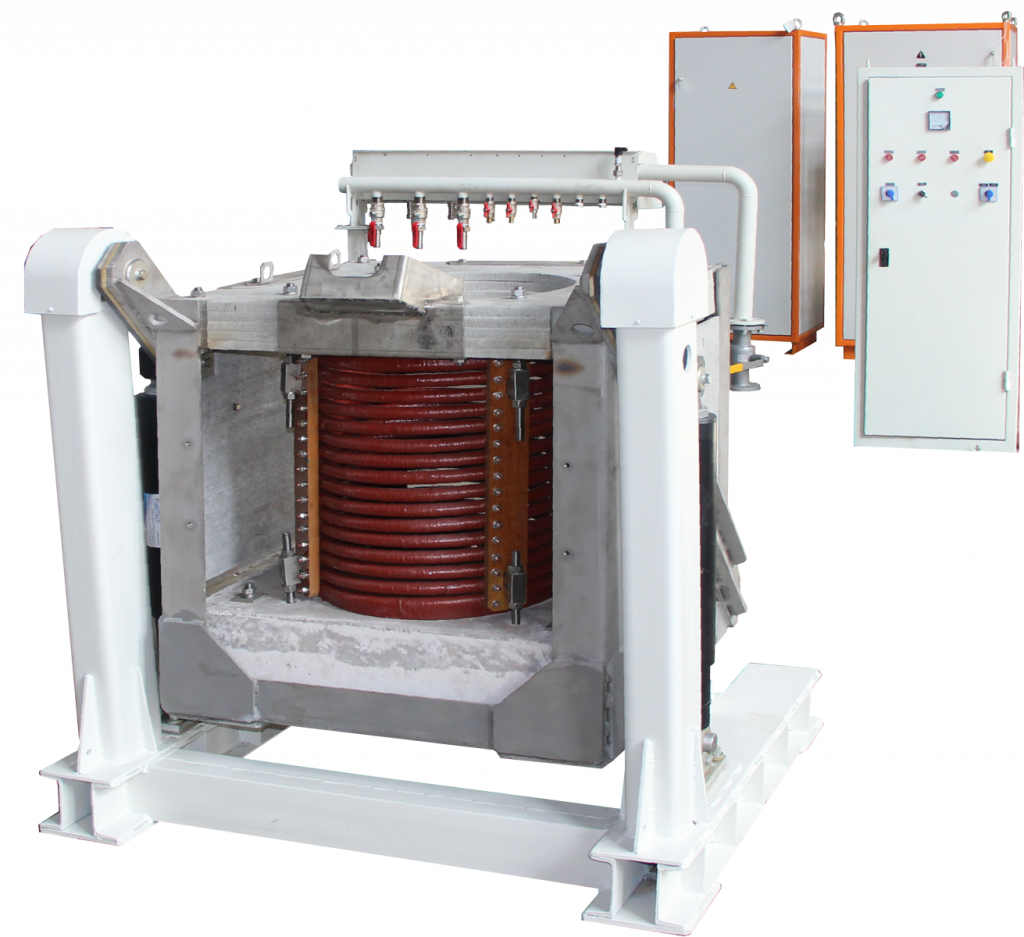

Plant for induction melting type "PPI-0.45"

The furnace for induction melting type "PPI-0.45" is intended for melting steels, cast iron, non-ferrous alloys in a stuffed crucible with subsequent pouring of molds or flasks. The plant ensures the production of shaped castings.

The furnace "PPI" consists of units:

1. Melting unit,

2. Thyristor frequency converter,

3. Hydraulic system,

4. Water cooling system,

5. Control panel,

6. Frame,

7. Capacitor battery.

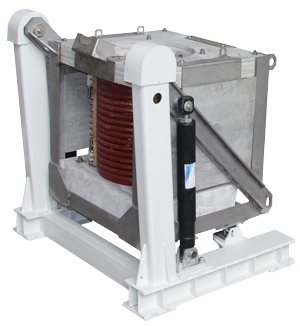

1. Melting unit.

The design of the melting unit is a water-cooled inductor installed inside a magnetic housing. The inductor is a multi-turn water-cooled coil of a special profile made of thick rectangular copper pipes.

2. Thyristor frequency converter.

The thyristor frequency converter is made according to the circuit of an adjustable rectifier with subsequent inversion.

Converter protection protects the power electronics from external factors, such as: overvoltage, inductor short circuit, inverting failure, lack of cooling water pressure, etc.

3. Hydraulic system.

The drive for turning the melting unit for draining metal is hydraulic. The hydraulic system includes: a hydraulic station, high-pressure hoses, actuators-hydraulic cylinders.

4. Water cooling system.

The water cooling system serves to supply and drain cooling water to the inductor coil, as well as to the capacitor battery and power source. The system collector is made of corrosion-resistant steel and shut-off valves, the system controls the temperature of the cooling water, the presence of flow in the circuits and the pressure of the supplied liquid at the entrance to the system.

5. Control panel.

The power source is controlled either through the remote control for local control, or through the operator control panel computer. All the main parameters of the power source are displayed on the computer screen, including power, frequency, voltage, the status of all sensors, and electricity consumption readings.

6. Frame.

The frame is the supporting structure of the melting furnace and the turning hydraulic cylinders.

Furnaces of the “PPI” type are produced in the modifications of “PPI-0.16”, "PPI-0.25" and "PPI-0.45", the crucible capacity of each is 16, 25 and 45 cubic dm, respectively.

The furnace "PPI" consists of units:

1. Melting unit,

2. Thyristor frequency converter,

3. Hydraulic system,

4. Water cooling system,

5. Control panel,

6. Frame,

7. Capacitor battery.

1. Melting unit.

The design of the melting unit is a water-cooled inductor installed inside a magnetic housing. The inductor is a multi-turn water-cooled coil of a special profile made of thick rectangular copper pipes.

2. Thyristor frequency converter.

The thyristor frequency converter is made according to the circuit of an adjustable rectifier with subsequent inversion.

Converter protection protects the power electronics from external factors, such as: overvoltage, inductor short circuit, inverting failure, lack of cooling water pressure, etc.

3. Hydraulic system.

The drive for turning the melting unit for draining metal is hydraulic. The hydraulic system includes: a hydraulic station, high-pressure hoses, actuators-hydraulic cylinders.

4. Water cooling system.

The water cooling system serves to supply and drain cooling water to the inductor coil, as well as to the capacitor battery and power source. The system collector is made of corrosion-resistant steel and shut-off valves, the system controls the temperature of the cooling water, the presence of flow in the circuits and the pressure of the supplied liquid at the entrance to the system.

5. Control panel.

The power source is controlled either through the remote control for local control, or through the operator control panel computer. All the main parameters of the power source are displayed on the computer screen, including power, frequency, voltage, the status of all sensors, and electricity consumption readings.

6. Frame.

The frame is the supporting structure of the melting furnace and the turning hydraulic cylinders.

Furnaces of the “PPI” type are produced in the modifications of “PPI-0.16”, "PPI-0.25" and "PPI-0.45", the crucible capacity of each is 16, 25 and 45 cubic dm, respectively.

Technical data

Crucible capacity, dm3

45

Operating temperature, °C

1350

Productivity, kg per day

150

Batch size, mm

50 - 100

Melt drain

Turning

Temperature control

Immersion thermocouple

Overall dimensions (L*W*H), mm

4500*2900*2190

Water cooling system

Closed

Cooling water consumption, m3/h

7,5

Optional equipment

Exhaust system with filters for catching sublimates and a rotating hood over the melting and casting units

Submit an inquiry

Прошлое

Настоящее

Будущее

Личный Кабинет

Личный Кабинет